ABOUT US

Jiangyin Kaixin Forging Co., Ltd.

The company was founded in March 2011 and is located in the beautiful national sanitary city-No. 12, Xiaguang Road, Qiaoqi Industrial Park, Xuxiake Town, Jiangyin City, Jiangsu Province. It covers an area of 10,000 square meters and a workshop area of 5,000 square meters. The total assets of the company There are 25.8 million yuan and there are 26 employees, including 2 senior engineers and 8 technicians. The company mainly produces large displacement motorcycle horizontal bars and multi-cylinder crankshafts, universal joints, protruding element forks, automobile lifting lugs, steering hanging arms, compressor eccentric shafts, medical equipment valve bodies, flanges and other forging products, which have passed TS16949 quality System Certification. The company has produced more than 100 kinds of crankshafts with an annual output of more than 500,000 pieces.

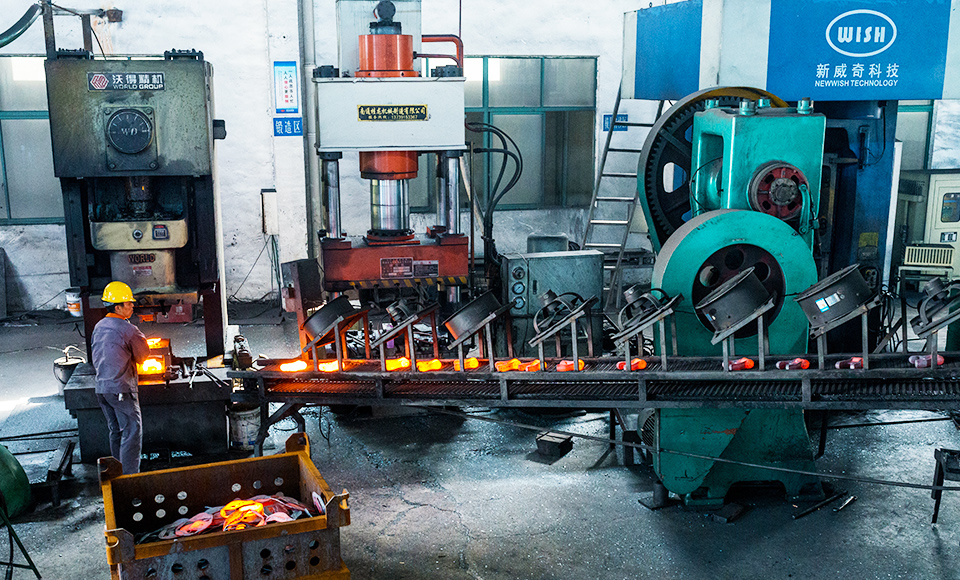

The production process is: raw material storage test-blanking-intermediate frequency heating-billet making-forging-shot blasting-flaw detection-factory inspection, and strictly in accordance with the quality system requirements procedures, control, production, product quality Can meet various customer requirements.

The company's geographical position is superior. The Beijing-Shanghai Expressway in the territory is connected to the South Jiangsu Expressway along the Yangtze River, and it is accessible via the exit of Xia Ke Station. It only takes more than an hour to reach Shanghai International Pudong and Hongqiao Airport directly. It is adjacent to Wuxi Station of Shanghai-Nanjing Railway in the south and Jiangyin Port on the south bank of the Yangtze River in the north by the Golden Waterway.

Why Choose Us?

Differential crankshaft blank

Win-win cooperation with multiple first-line brand motorcycle manufacturers

The company has produced more than 100 kinds of crankshafts with an annual output of more than 500,000 pieces. The production process is: raw material storage test-blanking-intermediate frequency heating-billet making-forging-shot blasting-flaw detection-factory inspection, and strictly in accordance with the quality system requirements procedures, control, production, product quality Can meet various customer requirements.

Attitude: Determines Everything

Detail: Determines Success or Failure

Goal: Determines Direction

Action: Creates the Future

Production Process

The company has produced more than 100 kinds of crankshafts with an annual output of more than 500,000 pieces. The production process is: raw material storage test-blanking-intermediate frequency heating-billet making-forging-shot blasting-flaw detection-factory inspection, and strictly in accordance with the quality system requirements procedures, control, production, product quality Can meet various customer requirements.

Certification

The company mainly produces large displacement motorcycle horizontal bars and multi-cylinder crankshafts, universal joints, protruding element forks, automobile lifting lugs, steering hanging arms, compressor eccentric shafts, medical equipment valve bodies, flanges and other forging products, which have passed TS16949 quality System Certification. The company has produced more than 100 kinds of crankshafts with an annual output of more than 500,000 pieces.